What is pipeline corrosion?

Pipeline corrosion occurs naturally and continuous,it refers to the degradation and destruction of metal materials caused by chemical and electrochemical interactions between metal materials and environmental media.It can have a negative impact on the integrity and longevity of the pipeline.Pipe materials affected by corrosion include metal and non-metal pipes,pipe joints,welds and surface coatings.The corrosion can occur on both internal and external of the pipes.Therefore,anti-corrosion is the primary problem to be considered in pipeline.So how to avoid it?

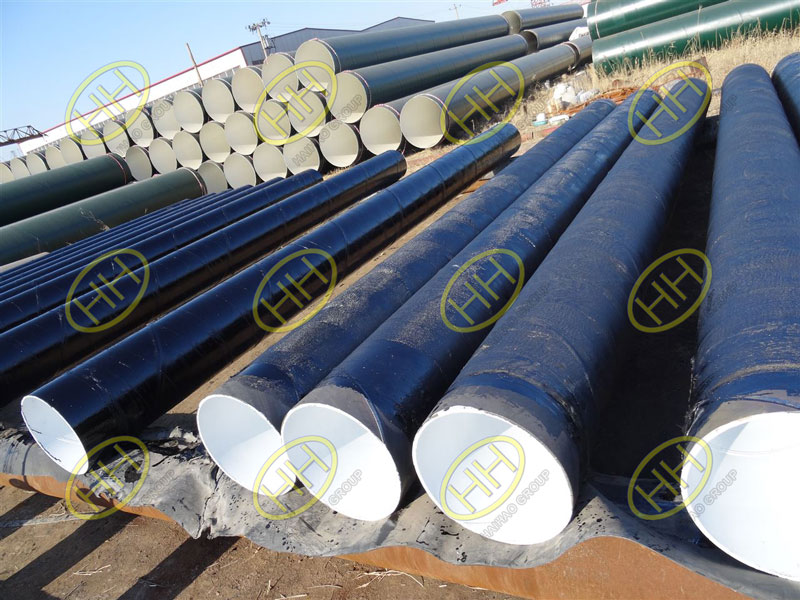

Anti-corrosive coating asphalt coated steel pipes

Ways to avoid pipeline corrosion:

Preventing corrosion requires elimination or suppression using two principal methods,cathodic protection and anti-corrosion coatings.Generally,cathodic protection systems are used in conjunction with coating systems.

Pipeline material:

The use of pipeline materials can also significantly affect corrosion.The use of materials such as stainless steel or special alloys can improve the service life of pipes,while steel or steel reinforced concrete is prone to corrosion.

Corrosion inhibitors:

Corrosion inhibitor is a compound added in the upstream pipeline,which can inhibit the corrosion of carbon and low-alloy steel pipes.

Fusion bonded epoxy(FBE) coating steel pipe

Anti-corrosive coatings:

Anti-corrosive coating is one of the best methods to control pipeline corrosion.Coating is a method of preventing corrosion of pipes.Choosing the right coating can greatly reduce the corrosion of pipeline.The internal and external area of the pipe can both be corrosive because of different factors.The external pipeline corrosion can mainly due to the surroundings,such as acid soil,wet conditions and so on.Factors that lead to internal corrosion are the oxygen content,temperature,pressure and flow rate of the liquid carried in the pipelines.Due to the above reasons,the anti-corrosive pipeline coating can be put into two corresponding categories,the internal and external corrosion-resistant coating.

- Internal anti-corrosion coating:

Common technical methods include epoxy powder coating technology,liquid epoxy coating technology and other coating technologies. - External anti-corrosion coating:

Commonly used external anti-corrosive coating materials:1.bitumen coating,2.coal tar enamel coating,3.epoxy bitumen coating,4.tape coating,5.polyethylene coating,6.fusion bonded epoxy coating(FBE coating),7.Three-layer PE/PP coating(3LPE or 3LPP)

3PE anti corrosion coating steel pipes

Cathodic protection

Cathodic protection(CP) is a method to control corrosion by using a direct electrical current which neutralizes external corrosion typically associated with metal pipe.It is generally used when a pipeline is buried underground or in water. When executed on a new pipeline, cathodic protection can prevent corrosion from the start. On an older pipeline, cathodic protection can impede existing corrosion of the line.There are two methods of cathodic protection:

- Sacrificial anodes:

The steel in the pipelines has both cathodic and anodic.The anodic areas are the places that corrode,so as part of galvanic or anodic pipeline cathodic protection,sacrificial anodes are attached or combined with the pipeline so that the pipeline itself does not be corroded.The sacrificial anode can be made of a variety of materials,depending on the material used in the pipe.Aluminum and magnesium alloys are usually used.This basically means that the entire pipe becomes a cathode and the sacrificial anode corrodes.This type of protection does not require an external power source because the material itself will allow the current to flow naturally.The sacrificial anode will eventually become totally corroded and will need replacement as the pipeline structure ages. - Impressed current systems:

Impressed current pipeline cathodic protection(ICCP) systems are generally used in larger structures because the galvanic anodes are not capable of producing enough current to provide sufficient cathodic protection. The impressed current requires a DC power source. Usually, other power sources are used and converted to the necessary DC.A variety of materials may be used as anodes for the impressed current.

Haihao Group supply pipeline products more than 30 years,which contain butt welding pipe fittings,forged pipe fittings,flanges and steel pipes.The products materials can be carbon steel,alloy steel and stainless steel.The anti-corrosive coating contain bitumen coating,coal tar enamel coating,epoxy bitumen coating,tape coating,polyethylene coating,fusion bonded epoxy coating(FBE coating),three-layer PE/PP coating(3LPE or 3LPP),etc.If you want to know more about our piping products,please email us:sales@haihaogroup.com