The external pipeline corrosion can mainly due to the surroundings,such as acid soil,wet conditions and so on.So the external anti-corrosive coating for pipeline are very important.There are the commonly used external anti-corrosive coating materials for pipeline.

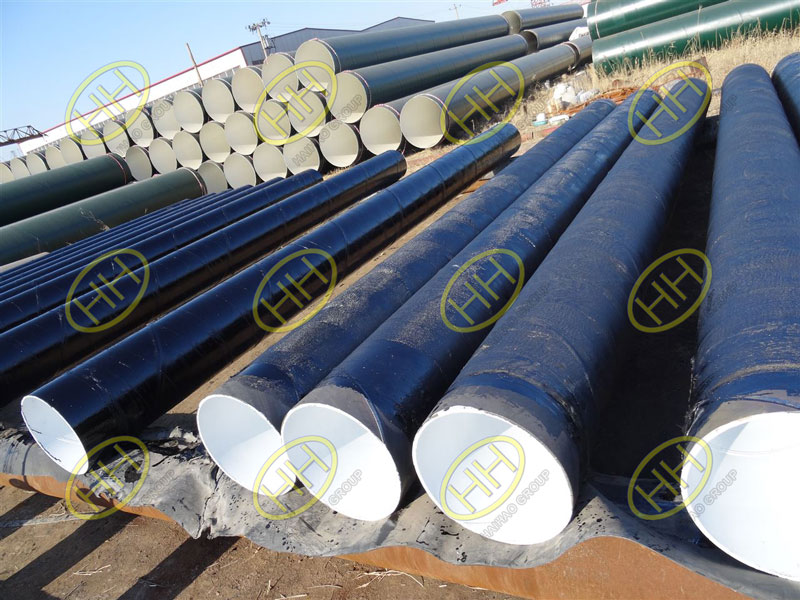

Anti-corrosive coating asphalt coated steel pipes

Petroleum asphalt or petroleum bitumen:

As the earliest anti-corrosion material for pipelines,petroleum bitumen is almost entirely used as anti-corrosion material in long-distance pipelines in China due to its characteristics of rich sources,low cost,safety and reliability, and strong construction adaptability.Petroleum asphalt anti-corrosive layer application time is long,rich experience, mature technology,equipment finalize the design.But compared with coal-tar enamel,plastic and other materials,its main disadvantages are large water absorption rate,poor aging resistance,not resistant to bacterial corrosion.

Coal-tar enamel:

Coal tar enamel has the characteristics of low water absorption rate, good electrical insulation performance,anti-bacterial corrosion and so on.The main reason why the coal tar enamel is restricted in use is that it is toxic during hot compress.

Epoxy coal tar:

Epoxy coal tar anti-corrosive coating is composed of epoxy resin,coal tar,curing agent and rust-proof pigment.It has high strength,good insulation,water resistance,heat resistance,corrosion resistance medium,anti-bacterial and other properties,and it is suitable for underwater pipeline and metal structure anti-corrosion.At the same time,it has the advantages of simple construction (cold coating technology),safe operation and less construction machine,so it is superior to petroleum asphalt and coal tar enamel.However,epoxy coal asphalt anti-corrosive coating is a thin coating with a total thickness of less than 1mm,and strict requirements on the surface treatment of steel pipe, environmental temperature,humidity and other conditions.A slight negligence will produce pinholes and affect the ant-corrosive effect.Therefore,it is difficult to control the quality in site construction.

Fusion bonded epoxy(FBE) coating steel pipe

Sealing tape:

Pressure sensitive adhesive tape is made of plastic tape substrate,coated with pressure sensitive adhesive (about 0.1mm thick).It is a kind of anti-corrosion material which is made of special adhesive applied on polyethylene strip mixed with various anti-aging agents.It has pressure-sensitive bonding property at room temperature,and it can solidify with metal when the temperature rises.It can form a complete sealing anti-corrosive layer on the pipe surface.The plastic base band bears the anti-corrosion function of pressure-sensitive adhesive tape, and the adhesive is only used as the adhesive medium during winding.Polyethylene adhesive tape has good anti-corrosion insulation performance,convenient construction,no pollution,low price,reliable anti-corrosion quality.

Polyethylene coating:

Polyethylene plastic hot extrusion on the surface of the pipe after treatment, forming a tight bond on the wall of the continuous hard plastic shell, commonly known as “jacket”.It has the advantages of good corrosion resistance, high mechanical strength, low cost of raw materials and wide range of applicable temperature.For small diameter pipe has successful experience,but for large diameter pipe diameter prone to “jacket cracking” problem,also makes the application of polyethylene coating is limited.The method to solve the problem is to use polyethylene thermal shrinkage sleeve (tape, sheet) patch.

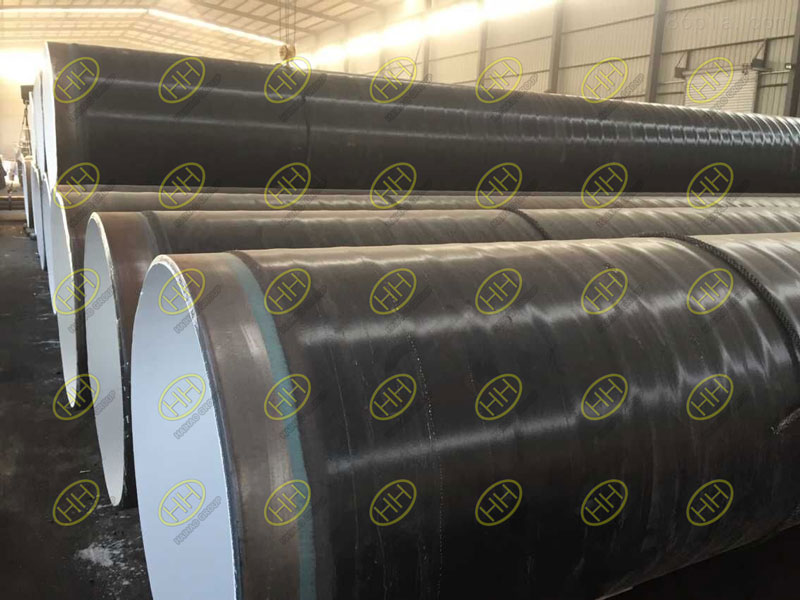

3PE anti corrosion coated steel pipes

Fusion bonded epoxy coating(FBE)

Fusion bonded epoxy(FBE) coating generally refers to a single layer of fused epoxy coating, using fused epoxy powder coating as a film-forming material. This kind of epoxy powder coating is a kind of thermosetting coating, which is made of solid epoxy resin, curing agent and various additives through mixing and grinding.Fusion bonded epoxy (FBE) coating is a powder coating broadly used to provide protection to pipelines, steel pipes and a wide range of piping bonds.FBE Coating has been used as a standard in industries for protection against corrosion.

Polyethylene three layer anti-corrosion coating(3PE)

The 3PE coated steel pipe is with 3 layer coatings,the first layer of epoxy powder (FBE> 100um),the second adhesive(AD) 170-250um,the third layer of polyethylene (PE) 2.5-3.7mm.Thus the 3PE coated steel pipe enjoys good performance-abrasive resistance,shock resistance,acid resistance,high quality and long service life.

3PE coating pipe integrated with the advantages of FBE and the PE.This is getting more and more widely used in buried pipeline’s transporting of water,gas and oil.

Haihao Group has imported the most advanced international and domestic anti-corrosion product lines,such as the two/three layer structured polyolefin(PE, PP) and fusion bond epoxy powder(FBE) steel pipe external coating production lines. We are professional sales of seamless steel pipe,SSAW,ERW,LSAW,hot dipped galvanized steel pipe and precision seamless steel pipes.For any request for flange pipe and fittings,free to contact us,email:sales@haihaogroup.com