Stainless Steel 304 Street Elbow

A street elbow (sometimes called a street ell or service ell) is a type of plumbing or piping fitting intended to join a piece of pipe and another fitting at an angle. The difference between a street elbow and a regular elbow is the nature of the connections on either end.

A regular elbow has a female hub or FIP connection on both ends. A hub is a female ABS, PVC or copper pipe receptacle; FIP denotes “Female Iron Pipe” threads, that is, it receives threaded MIP iron, brass or plastic pipe on both ends. FIP is also known as FPT, Female Pipe Thread, and MIP is also known as MPT, Male Pipe Thread. Collectively, these are known as National Pipe Thread (NPT) fittings.

Instead, a street elbow has a female fitting (hub or FIP) on one end and a male pipe or MIP fitting on the other end. The advantage of the street elbow is that it can be connected directly to another fitting without having to use an additional short connecting piece called a pipe nipple.

Street elbows are available in 90°, 45° and 22.5° bends. They can be used in water supply, drainage, sewers, vents, central vacuum systems, compressed air and gas lines, HVAC, sump pump drains, and any location where plumbing fittings would be used to join sections of pipe. The Natural Gas and Propane Installation Code of Canada (B149.1) states “…a street elbow or a street tee shall not be used in a piping system”.

Street elbows are a type of pipe fitting with male threads on one end and female threads on the other. These fittings can typically be used in tighter quarters than regular elbows since no pipe nipple is required, unlike regular elbows that have two sets of female threads.

Street elbows commonly have a 90 degree bend, though 22.5 and 45 degree versions can also be found. The etymology of the name is not certain, though it may come from the the fact that these fittings are commonly found where sewer, water, and gas lines connect to a utility at the street. A variety of applications make use of street elbow fittings, including water supply, gas, and sewage systems.

Regular pipe elbows have female fittings on both ends, either in the form of a receiver for copper or acrylonitrile butadiene styrene (ABS) pipe, or as traditional iron threads. In order to connect another female pipe to one of these traditional elbows, a fitting known as a pipe nipple is required. This short fitting has two sets of male threads and can add extra length to the final setup. A street elbow can do away with the need for a pipe nipple since one end of the fitting already has male threads.

The main advantage that a street elbow offer is there are less joints to leak and fewer parts to carry around. Since a regular elbow typically requires a pipe nipple, they result in systems that are inherently more complex. The pipe nipple can also increase the combined length of the joined pipes, so street elbows are often useful in cramped quarters. Regular elbow connections offer some more flexibility because they have the ability to accept male pipe threads on both ends. This can be seen as a trade off, since the increased flexibility also means pipe nipples will be required for many jobs. Street elbows are often used to connect sewage or water lines to the utility.

They are also commonly used to join a meter box to a pipe at the point that it leaves the street, which may be the origin of the name. Another theory is that the name comes from the abbreviation st. fitting, which originally indicated a spigot fitting. As abbreviation st. often refers to street, the name street elbow may have originally come from a misunderstanding. A spigot elbow is very similar to a street elbow, though they typically involve slip fittings instead of pipe fittings.

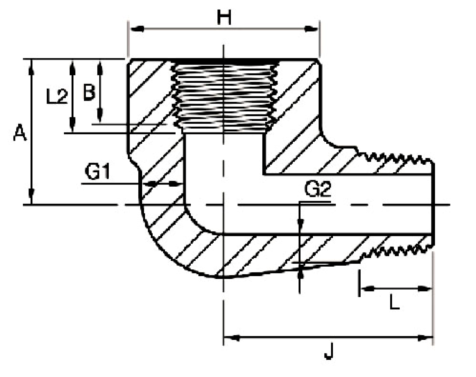

ASME B16.11 Threaded/Screwed Street Elbow Dimension

| Class | NPS | H | A | J | G1 | G2 | B | L2 | L |

| 3000 | 1/8″ | 19 | 19 | 25 | 3.18 | 2.74 | 6.4 | 6.7 | 10 |

| 1/4″ | 25 | 22 | 32 | 3.3 | 3.22 | 8.1 | 10.2 | 11 | |

| 3/8″ | 32 | 25 | 38 | 3.5 | 3.5 | 9.1 | 10.4 | 13 | |

| 1/2″ | 38 | 28 | 41 | 4.09 | 4.16 | 10.9 | 13.6 | 14 | |

| 3/4″ | 44 | 35 | 48 | 4.32 | 4.88 | 12.7 | 13.9 | 16 | |

| 1″ | 51 | 44 | 57 | 4.98 | 5.56 | 14.7 | 17.3 | 19 | |

| 1 1/4″ | 62 | 51 | 66 | 5.28 | 5.56 | 17 | 18 | 21 | |

| 1 1/2″ | 70 | 54 | 71 | 5.56 | 6.25 | 17.8 | 18.4 | 21 | |

| 2″ | 84 | 64 | 84 | 7.14 | 7.64 | 19 | 19 | 22 | |

| 6000 | 1/8″ | 25 | 22 | 32 | 5.08 | 4.22 | 6.4 | 6.7 | 10 |

| 1/4″ | 32 | 25 | 38 | 5.66 | 5.28 | 8.1 | 10.2 | 11 | |

| 3/8″ | 38 | 28 | 41 | 6.98 | 5.59 | 9.1 | 10.4 | 13 | |

| 1/2″ | 44 | 35 | 48 | 8.15 | 6.53 | 10.9 | 13.6 | 14 | |

| 3/4″ | 51 | 44 | 57 | 8.53 | 6.86 | 12.7 | 13.9 | 16 | |

| 1″ | 62 | 51 | 66 | 9.93 | 7.95 | 14.7 | 17.3 | 19 | |

| 1 1/4″ | 70 | 54 | 71 | 10.59 | 8.48 | 17 | 18 | 21 | |

| 1 1/2″ | 84 | 64 | 84 | 11.07 | 8.89 | 17.8 | 18.4 | 21 | |

| 2″ | 102 | 83 | 105 | 12.09 | 9.7 | 19 | 19 | 22 |