Insulated joints are usually produced in accordance with customer requirements, material, size, coating and inspection… For example,the following drawing requirements.

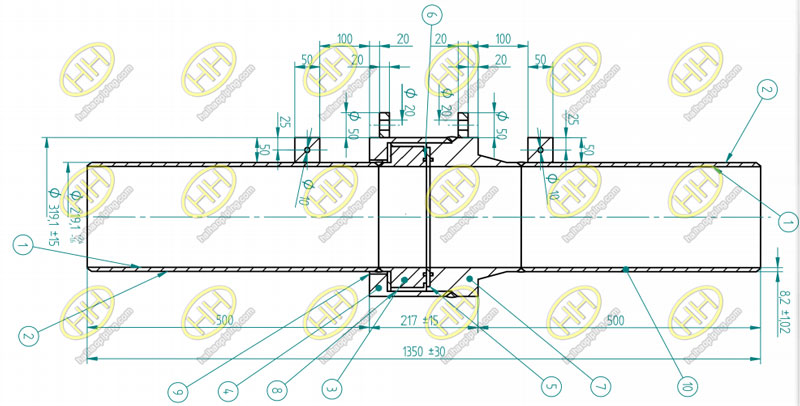

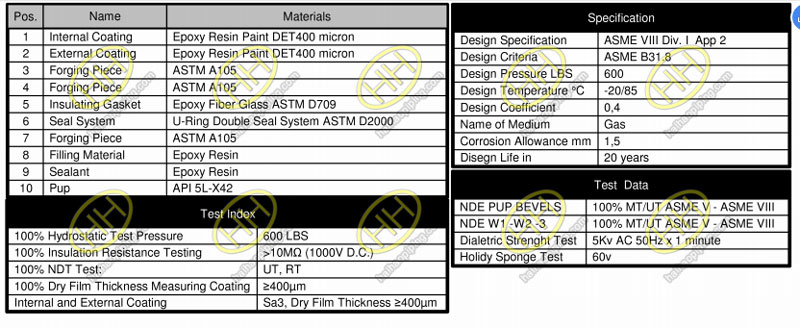

Monolithic Insulating Joint Data

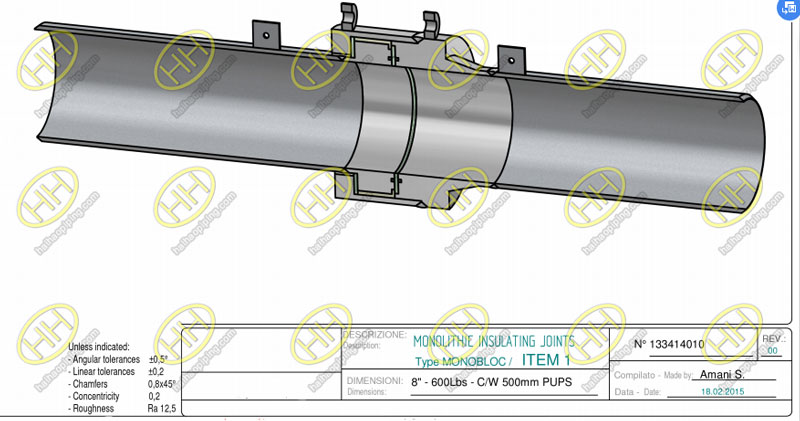

1.Structural characteristics of insulated joint

Insulated joints are in the form of integral extrusion welding and shall not be bolted or flanged.The insulating joint is in the form of sandwiching and fixing the insulating and sealing material into the sleeve. After the insulation joint is assembled, the internal components should be fixed in place. The entire insulated joint remains intact under soil pressure, specified piping operating pressure, and water pressure testing. The insulating joint sealing element abuts against the insulating plate inside the joint, and has permanent elasticity, and the two sides of the sealing element directly contact with the bare metal surface do not move, ensuring the tightness of the joint.

Monolithic Insulating Joint Specification

2.Insulated Joint Features

Good insulation performance: 2500V shaking table test insulation resistance ≥200MΩ, breakdown voltage ≥3KV.

Long life: same life and equal strength as pipeline.

High strength: pressure test ≥ 1.5PN (design pressure).

Use temperature: -30 ° C – +90 ° C.

Applicable medium: oil, gas, water, chemical raw materials, coal slurry, etc.

Monolithic Insulating Joint Drawing

3.Material characteristics of insulated joint

Insulation: High-strength epoxy resin and glass fiber layered conforming material: ASTM D709 G11.

Bending strength: longitudinal ≥ 390 MPa, transverse ≥ 290 MPa;

Tensile strength: longitudinal ≥ 340MPa, transverse ≥ 240MPa;

Compressive strength: ≥ 340MPa;

Water absorption: ≤ 30mg;

After immersion, the resistance is ≥5*108Ω

Breakdown voltage ≥3.0KV

Combined steel body: 16Mn, JB4726, ASTM A694 F52, F60

Short tube: 20#, 16Mn, GB8163-99; X70, X65, X56, X52, X46, API SPEC.5L.

Sealing material: O-shaped or U-shaped sealing ring: fluororubber, nitrile butadiene rubber, in accordance with ASTM D2000.

Filling material: cold-setting resin;

Insulating coating; imported liquid epoxy resin;

Anticorrosive material: heat shrinkable anticorrosive material;

Haihao Group manufacture & supply butt welding pipe fittings,forged pipe fittings,steel pipes and flanges in different dimensions,standards and materials.If you want to know more about piping products,please email us:sales@haihaogroup.com