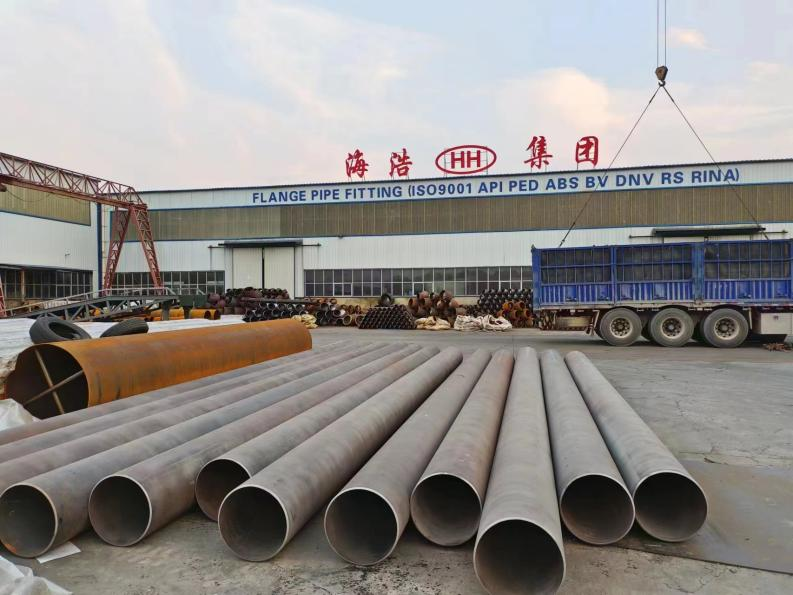

In critical industries such as oil & gas and petrochemical sectors, ensuring the integrity of piping components is non-negotiable. Haihao Group’s recent delivery of Nickel Alloy and Carbon Steel fittings to Singapore highlights the importance of material certification and non-destructive testing.

HAIHAO GROUP

Full Traceability with EN 10204 3.1 Certification

Every fitting and flange was delivered with an EN 10204 3.1 Mill Test Certificate, confirming compliance with technical standards. The certificates specify:

- Chemical composition

- Mechanical properties

- Heat treatment method

- Cooling medium used

- NACE MR0175/ISO 15156 Compliance for Sour Environments

All products meet NACE MR0175/ISO 15156 standards, ensuring safe usage in environments exposed to hydrogen sulfide (H₂S), which can cause sulfide stress cracking.

Importance of Non-Destructive Testing (NDT)

Haihao Group carried out comprehensive testing to verify the reliability of each component:

- Hardness testing to confirm mechanical properties

- Heat treatment reports to ensure microstructure control

- Ultrasonic Testing (UT) for detecting internal defects without damaging the material

Strict adherence to international standards, combined with rigorous testing, ensures that Haihao Group’s products deliver superior performance and reliability in critical applications. Our commitment to quality protects client projects from costly failures and downtime. Email:sales@haihaogroup.com