Penetrant testing(PT),also called dye penetrant inspection(DPI) or liquid penetrant inspection(LPI),is one of the most common,low cost solution,oldest methods of nondestructive testing.

Principles of dye penetant inspection(DPI):

DPI is based upon capillary action,the ability of a liquid to flow into narrow spaces without the assistance of,or even in opposition to,external forces like gravity—to detect surface-breaking defects.

After applying the penetrant and letting it dwell for a certain period of time,the excess is removed and a developer is applied. The developer draws the penetrant from surface-breaking defects where it seeped,revealing their presence.Inspection is performed under ultraviolet or white light, depending on the type of dye used – fluorescent or nonfluorescent (visible).

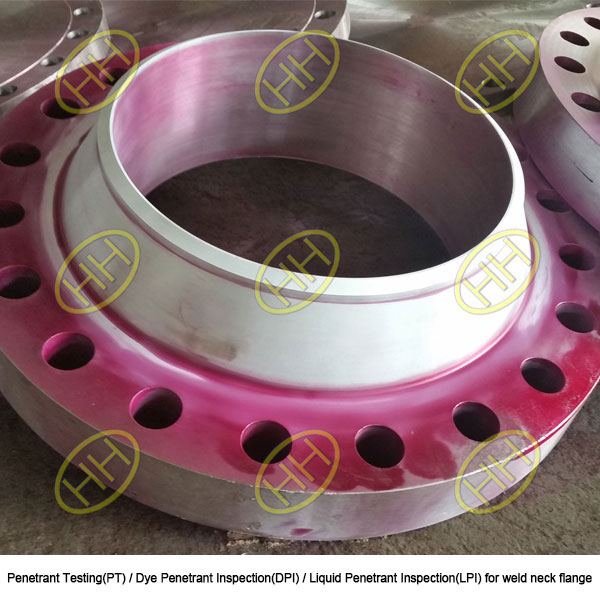

penetrant testing or dye penetrant inspection or liquid penetrant inspection for weld neck flange

The penetrant testing process:

1.Pre-cleaning:

The test surface is cleaned to remove any dirt,paint,oil,grease or any loose scale that could either keep penetrant out of a defect,or cause irrelevant or false indications.

2.Application of penetrant

The penetrant is then applied to the surface of the item being tested.The penetrant is usually a brilliant coloured mobile fluid with high wetting capability.It is then left to site for an amount of time to allow as much dye penetration as possible.

3.Excess penetrant removal

In this step, the inspector carefully removes excess penetrant without removing penetrant from the defects. Water or emulsifiers are sometimes used.The removal method is controlled by the type of penetrant used.Water-washable, solvent-removable, lipophilic post-emulsifiable, or hydrophilic post-emulsifiable are the common choices.

4.Application of developer

A layer of developer is applied to the surface,drawing penetrant out of flaws and to the surface,making it visible.Several developer types are available,including:non-aqueous wet developer,dry powder,water-suspendable,and water-soluble.Choice of developer is governed by penetrant compatibility(one can’t use water-soluble or -suspendable developer with water-washable penetrant),and by inspection conditions.

5.Inspection

With the aid of proper lighting,visual inspection is performed to detect any indications that may be present.

6.Cleaning

The last step is to remove the developer material from the areas of the surface lacking in defects.

penetrant testing or dye penetrant inspection or liquid penetrant inspection for large caliber elbow weld

Advantages of LPI

It is generally accepted that liquid penetrant testing has the following advantages:

- Sensitive to small surface discontinuities

- Few material limitations-works on metallic,non-metallic,magnetic,non-magnetic,conductive,and non-conductive materials

- Works on complex geometric shapes

- Visual,real-world results

- Liquid penetrant testing materials are very portable

- Liquid penetrant testing materials are individually very affordable

Disadvantages of LPI

However,liquid penetrant testing is not without several disadvantages:

- Only sensitive to surface-breaking defects

- Extensive,time-consuming pre-cleaning critical-surface contaminants can mask defects

- Only works on relatively non-porous surface materials

- Direct access to the surface under test necessary

- Multi-process testing procedure

- No depth sizing

- No recordable data available for progress monitoring

- Time-consuming post-cleaning also necessary

- Environmental concerns-may require costly handling and disposing of chemicals

- User dependent

A layer of developer is applied to the large caliber elbow weld

Haihao Group manufacture steel pipes,butt welding pipe fittings,forged pipe fittings and flanges products more than 30 years,our quality inspection department can carry out the NDT inspection as per clients requirement.If you have any questions,please email us:sales@haihaogroup.com