Anti-corrosion steel pipes,through the preservative process,is to prevent steel pipes from corroding or to slow down the corrosion in the chemical or electro chemical reaction during the transportation and application.Anti-corrosion steel pipes are mainly used for petroleum,chemical,gas,heat,sewage treatment,water,bridges,steel pipes and other engineering fields.Anti-corrosion steel pipe is divided into the following categories: FBE epoxy powder corrosion, 2PE/3PE corrosion, coal tar epoxy anti-corrosive,high-density polyethylene jacket corrosion.

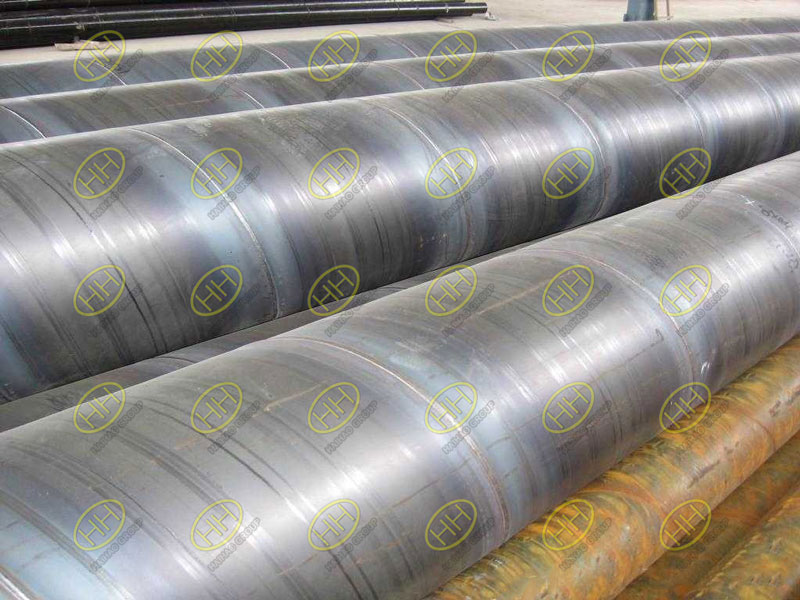

Spiral submerged arc welding steel pipes SSAW pipes

Spiral steel pipe in the actual construction, long-term contact with liquid, air, soil and other media,so it need to add a layer of protection for products on corrode the metal surface to prevent corrosion and prolong the life spiral.So how to do the anti-corrosion surface treatment process of spiral steel pipes?

After the spiral steel pipe enters the unit,it is rolled by multiple rollers and gradually rolled the strip steel to form a circular open tube with clearance.The gap is controlled at ~ 3mm by squeezing the roller to adjust the amount of reduction,and the weld end is flushed.

(1)If the gap is too large,resulting in reduced proximity effect,lack of eddy heat weld together indirectly arising crystal fusion or cracking are not bad.

(2)If the gap is too small, causing the proximity effect increases,excessive heat welding,weld cause burning;or weld extruded to form a pit after rolling,affecting the quality of the weld surface.

After heating both sides of the tube to the welding temperature,the lower extrusion roller squeezes the metal particles to form a common mutual penetration and crystallization,forming a solid weld.If the extrusion pressure of spiral steel pipe is too small,the crystallizer will form a strength drop and crack force on a small amount of common weld metal.If the pressure is too high,it will make the extrusion weld metal,not only reduce the welding strength,but also will produce a lot of internal and external burrs,and even cause weld defects smooth.

Haihao Group manufacture spiral steel pipes(SSAW,LSAW),welded steel pipes and seamless steel pipes in different dimensions,specifications,standards,materials.And our steel pipes are corrosion-resistant.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com