Welding is a process of joining two metal pieces as a result of significant diffusion of the atoms of the welded pieces into the joint (weld) region.Welding is carried out by heating the joined pieces to melting point and fusing them together (with or without filler material) or by applying pressure to the pieces in cold or heated state.Here are the preparation before welding:

1.Selection

Because the X standard for the West-to-East Gas Pipeline uses a spiral steel pipe of DN813 × 9.5mm, the diameter is larger than that of the usual steel pipe, so it is more likely that the circumference of the two steel pipes is different, and the radius of curvature in some directions is different In this way, it is easier to produce a larger amount of wrong edges in the construction, which directly affects the welding quality of the entire weld. Therefore, it is recommended to measure the circumference of each end of each steel pipe before the steel pipe enters the site, and then have a rough distribution of the steel pipe. In the planning, the difference between the circumference of the two steel pipes to be welded should not exceed 3mm, so as to reduce the occurrence of defects caused by wrong edges.

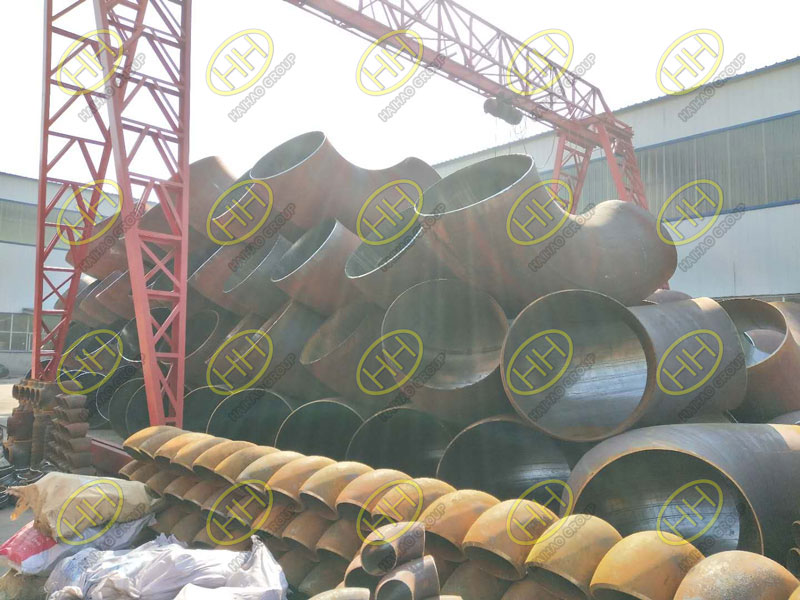

Large-diameter automatic welding elbows finished in Haihao Group

2.Bevel treatment

Bevel cleaning is very important for root welding, otherwise it is easy to produce defects such as internal bite, indentation, and air holes. To clean the bevel, you need to take out all the dirt on the inside of the bevel and within 25mm on both sides of the bevel.

3.Bevel polishing

Technical requirements for bevel grinding: Grind the inner side of the bevel to the appearance of metallic luster while not allowing damage to the bevel angle. Technical requirements for grinding of spiral welds: The spiral welds are required to be flush with the base material within 10mm on both sides of the groove, and a gentle transition of 30 degrees of elevation angle is required. The higher requirements for the grinding of the spiral weld bead are because the unpolished spiral weld and the pipeline weld constitute a cross weld, which causes three-dimensional stress and notch effects, which is easy to cause cracks, and the angle between the unpolished spiral weld and the base material is often There is rust, and air holes are likely to occur when the cover is covered. In addition, the spiral weld of the spiral steel pipe for welding excuses should be at least 100mm away to avoid stress concentration and defects.

4.Bevel preparation

In the preparation of the groove, pay special attention to the angle and blunt edge of the groove. Too large or too small will affect the quality of the weld. If the blunt edge is too large, it will not be fully penetrated. If the blunt edge is too small, it will easily burn. Wearing will affect the quality of root welding. Therefore, it should strictly follow the process requirements, generally choose between 1.5 ~ 2.0mm.