In the manufacturing of steel pipes and structural components, ERW (Electric Resistance Welding) and EFW (Electric Fusion Welding) are two commonly used welding methods. While both are classified as welded pipe processes, they differ significantly in terms of welding principles, equipment, filler metal usage, seam characteristics, and application scope.

ASME B36.10 ASTM A53 GR.B BE ERW pipes

This article provides a comprehensive comparison between ERW and EFW to help industry professionals select the right process for their project requirements.

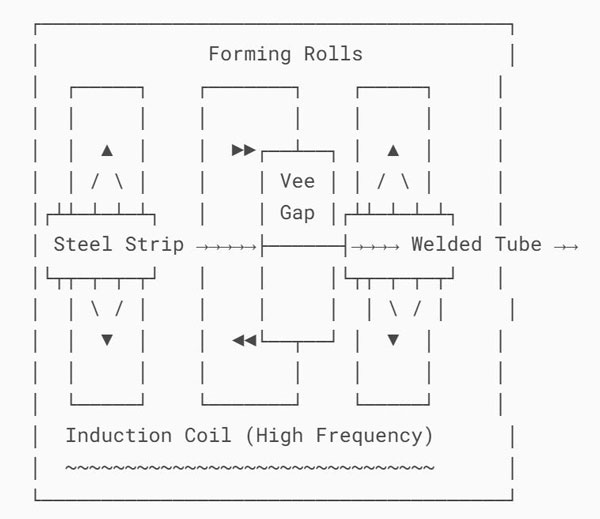

ERW Process Drawing

Core Welding Principles

| Feature | ERW (Electric Resistance Welding) | EFW (Electric Fusion Welding) |

| Heat Source | Electrical resistance (Joule heating) | Electric arc (high-temperature arc heating) |

| Filler Metal | Not required – uses only parent metal | Usually required – uses filler wire or rod |

| Pressure Applied | Yes – forging pressure is critical | Not essential – fusion via molten pool |

| Key Process Type | High-Frequency Welding (HFW), Flash Welding | Submerged Arc Welding (SAW), TIG, MIG, SMAW |

| Weld Pool Formation | No molten pool – surface heating and forging | Forms a full molten weld pool that solidifies into seam |

Welding Process Description

ERW: Electric Resistance Welding

ERW utilizes electrical resistance to generate localized heat at the joint. As two metal edges are brought together, high-frequency AC current passes through, causing resistance heating. The material softens or partially melts, and then forging pressure (squeeze rollers) is applied to fuse the edges.

No filler metal

Seam formed purely from base material

Seam is narrow and smooth

High-speed, continuous production

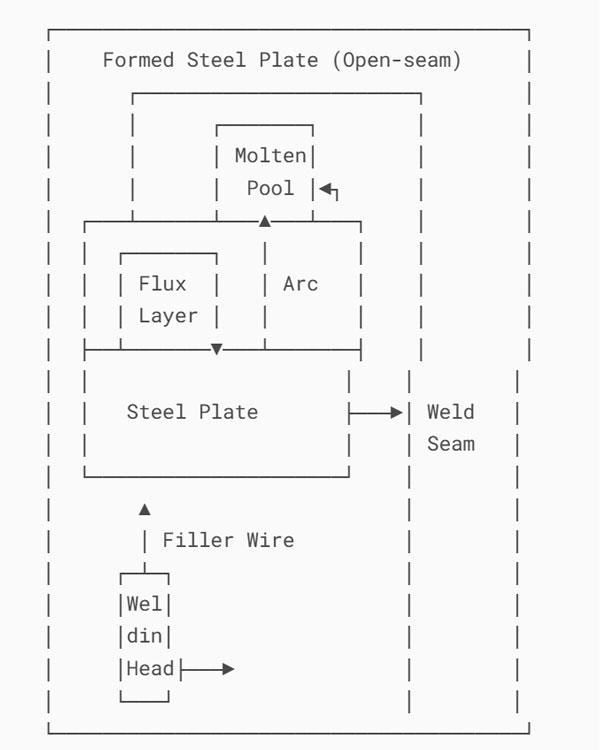

EFW Process Drawing

EFW: Electric Fusion Welding

EFW relies on an electric arc generated between an electrode and the workpiece. The arc melts the edges of the base material and the filler metal to form a molten weld pool. As the pool cools, it solidifies into a strong weld.

Uses filler metal

Arc-based melting of both edges and filler

Suitable for thick-walled pipes, exotic alloys

Greater control over weld chemistry

Technical Comparison Table

| Parameter | ERW | EFW |

| Heat Source | Resistance heat (no arc) | Arc welding |

| Filler Metal | Not used | Typically required |

| Pressure Requirement | High forging pressure | Minimal or none |

| Seam Width | Narrow, minimal heat-affected zone (HAZ) | Wider seam, larger HAZ |

| Weld Metal Composition | Same as base metal | Mixture of base and filler metal |

| Typical Defects | Incomplete fusion (oxide inclusions, gray spots) | Porosity, slag, undercuts, cracks |

| Surface Finish | Smooth and flush | May require grinding |

| Speed and Automation | Very fast, fully automated | Slower, more manual or semi-automated |

| Common Pipe Standards | API 5L, ASTM A53 | ASTM A358, A671, A312, A335 (for thicker pipes) |

| Cost Efficiency | High – ideal for mass production | Higher – suitable for specialty and high-performance pipes |

Applications by Process

| Application Area | Preferred Process |

| High-volume water/oil/gas pipelines | ERW |

| Structural tubing, automotive drive shafts | ERW |

| Thick-walled pressure piping | EFW (SAW) |

| Chemical and power plant piping | EFW |

| Nuclear and boiler-grade tubing | EFW |

| Pipe fittings and field joints | EFW (TIG, SMAW) |

Example Process Variants

ERW Techniques:

High-Frequency Welding (HFW): Most widely used ERW method for pipe production.

Flash Welding: Common in bar and pipe end joining.

EFW Techniques:

Submerged Arc Welding (SAW): Preferred for large-diameter, thick-walled pipes with excellent fusion and productivity.

Gas Tungsten Arc Welding (GTAW/TIG): Used for small-diameter pipe joints and clean, defect-free welds.

Shielded Metal Arc Welding (SMAW): Suitable for onsite piping connections and repairs.

Pros and Cons

| Process | Pros | Cons |

| ERW | Fast, low-cost, minimal material input, clean finish, high automation | Limited to thinner wall thickness, susceptible to oxide defects |

| EFW | Handles thick walls, better weld integrity, versatile across alloys | Slower, higher cost, more complex setup, post-weld treatment needed |

Real-World Implications

ERW is ideal for high-efficiency, cost-sensitive projects where moderate wall thickness and standard materials are used.

EFW is recommended for critical applications involving high pressure, corrosive media, or high-temperature service.

At Haihao Group, we manufacture and supply both ERW and EFW pipes according to international standards such as API 5L, ASTM A335, A358, A312, and A671. Whether you’re sourcing structural tubing or high-performance alloy pipes, our team can advise on the best process and product to meet your project’s needs.

Conclusion

ERW and EFW are not just two types of pipes — they represent fundamentally different welding philosophies:

ERW = Resistance + Pressure (fast, clean, cost-efficient)

EFW = Arc + Fusion (versatile, strong, quality-driven)

Choosing the right process depends on factors like pipe diameter, wall thickness, material type, production volume, and required performance standards.

Contact Haihao Group today to discuss your project specifications and get expert guidance on ERW and EFW pipe solutions. Email:sales@haihaogroup.com

Related Articles:

ERW vs EFW Steel Pipes: What’s the Difference?

What’s A672 electric fusion welded (EFW) steel pipe?

ASTM A671 CC70 Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures

ASTM A671 CC65 Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures