The previous article introduced the quenching and tempering of the heat treatment process.Today,we will introduce normalizing.

1.What is normalization?

Normalizing is a heat treatment that improves the toughness of steel. After heating the steel member to 30 ~ 50 ° C above the Ac3 temperature, the steel member is kept in the oven for a period of time and air-cooled. The main feature is that the cooling rate is faster than annealing and lower than quenching. During normalizing, the crystal grains of steel can be refined in a slightly faster cooling, which not only can obtain satisfactory strength, but also can significantly improve toughness (AKV value) and reduce Cracking tendency of components. After normalizing treatment of some low-alloy hot-rolled steel plates, low-alloy steel forgings and castings, the comprehensive mechanical properties of the material can be greatly improved, and the cutting performance is also improved.

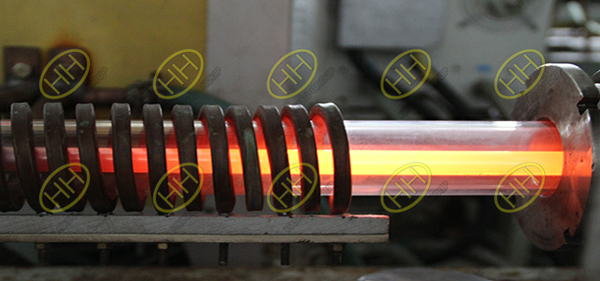

Normalizing + tempering of steel tubes

2.Normalizing has the following purposes and uses:

① For hypoeutectoid steel, normalizing is used to eliminate the overheated coarse-grained structure and Weiss structure of cast, forged and welded parts, the band structure in rolled materials; refine grains; and can be used as pre-heat treatment before quenching.

② For hypereutectoid steel, normalizing can eliminate reticulated secondary cementite and refine pearlite, which not only improves mechanical properties, but also facilitates subsequent spheroidizing annealing.

③ For low-carbon deep-drawn sheet steel, normalizing can eliminate free cementite at the grain boundaries to improve its deep-drawing performance.

④ For low-carbon steels and low-carbon low-alloy steels, normalizing can get more fine-grained pearlite structure, increase the hardness to HB140-190, avoid the phenomenon of “sticky knife” during cutting, and improve cutting processability . For medium carbon steel, normalizing and normalizing are more economical and convenient when both normalizing and annealing are available.

⑤ For ordinary medium-carbon structural steels, where the mechanical properties are not high, normalizing can be used instead of quenching and high temperature tempering, which is not only easy to operate,but also makes the structure and size of the steel stable.

⑥ High temperature normalizing (150 ~ 200 ℃ above Ac3) Due to the higher diffusion speed at high temperature, the segregation of components in castings and forgings can be reduced. The coarse grains after high temperature normalization can be refined by the subsequent lower temperature normalization.

⑦For some low and medium carbon alloy steels used in steam turbines and boilers, normalizing is often used to obtain bainite structure, and then tempering at high temperature has good creep resistance when used at 400 ~ 550 ℃.

⑧In addition to steel and steel, normalizing is also widely used in the heat treatment of nodular cast iron to obtain a pearlite matrix and improve the strength of nodular cast iron.

Because normalizing is characterized by air cooling, the ambient temperature, stacking method, airflow, and workpiece size all have an impact on the structure and performance of normalizing. Normalized structure can also be used as a classification method for alloy steel. Generally, alloy steel is divided into pearlite steel, bainite steel, martensitic steel,and austenitic steel based on the structure obtained by heating a sample with a diameter of 25 mm to 900 ° C and air cooling.