At Haihao Group, we understand the paramount importance of quality and reliability in the products we deliver to our valued customers. That’s why we employ stringent testing measures to ensure that every B36.10M BE A53 Gr.B ERW SCH40 pipe meets the highest standards of excellence. Recently, the batch of steel pipes ordered by Indian customers have been tested by NDT, and the test results meet the needs of customers.

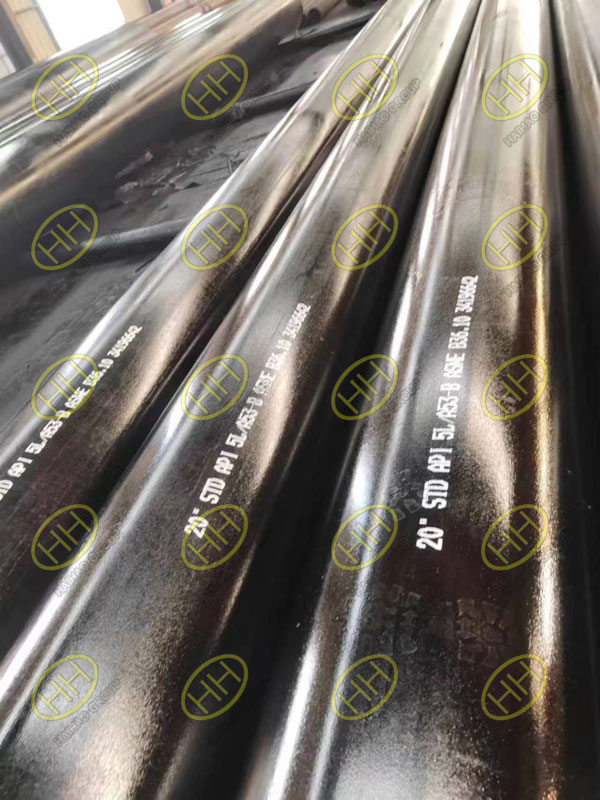

API 5L A53B ASME B36.10 steel pipes

Our NDT testing process encompasses various methods, including but not limited to:

Ultrasonic Testing (UT):

This method employs high-frequency sound waves to inspect the B36.10M BE A53 Gr.B ERW SCH40 pipe for internal and external defects. By transmitting ultrasonic waves through the pipe, we can identify inconsistencies in thickness, detect cracks, and determine the overall integrity of the material.

Magnetic Particle Testing (MT):

MT involves the application of magnetic fields to the surface of the B36.10M BE A53 Gr.B ERW SCH40 pipe. By introducing magnetic particles, we can identify surface-breaking defects such as cracks, fissures, or other imperfections that may compromise the pipe’s performance.

Visual Inspection (VI):

Visual Inspection is a fundamental part of NDT, allowing our experienced inspectors to visually examine the B36.10M BE A53 Gr.B ERW SCH40 pipe for any visible signs of defects, including surface irregularities, discontinuities, or deformations. Our inspectors utilize advanced visual inspection equipment to ensure a comprehensive assessment.

The significance of NDT testing for the B36.10M BE A53 Gr.B ERW SCH 40 pipe cannot be overstated. It provides our customers with the assurance that the pipe meets the required specifications and can perform optimally in demanding applications. By conducting NDT testing, we can identify any potential flaws early on, allowing us to take corrective measures and ensure the highest level of product quality and safety.

API 5L A53B ASME B36.10 steel pipes

Moreover, NDT testing helps us maintain compliance with international standards and industry regulations. It is a crucial step in our commitment to delivering reliable, durable, and defect-free B36.10M BE A53 Gr.B ERW SCH40 pipe to our customers.

At Haihao Group, we take great pride in our comprehensive NDT testing process. It enables us to provide our Indian customer with the utmost confidence in the quality and performance of the B36.10M BE A53 Gr.B ERW SCH40 pipe. By subjecting each pipe to rigorous NDT examinations, we ensure that it surpasses expectations and delivers exceptional value and longevity.

Choose Haihao Group as your trusted partner for top-quality pipes backed by rigorous NDT testing. Contact us today to discuss your specific requirements, and let us provide you with the assurance of excellence in pipe manufacturing and testing.