We know the common external surface defects of steel pipes,today let’s learn the common internal surface defects of steel pipes.

1.Inward fold

Features: Straight or spiral, semi-helical serrated defects appear on the inner surface of the steel pipe.

cause:

1) Tube blank: the center is loose and segregated; the residual shrinkage is serious; the non-metallic inclusions exceed the standard.

2) Uneven heating of the tube blank, excessively high or low temperature, and excessively long heating time.

3) Perforated area: severe wear on the plug; improper adjustment of the parameters of the punching machine; aging of the punching roller, etc.

Inspection: Inner folds are not allowed on the inner surface of the steel pipe. The inner folds of the pipe end should be ground or recut. The actual value of the wall thickness at the ground should not be less than the minimum value required by the standard;

FBE coating steel pipe

2.Internal scarring

Features: The inner surface of the steel pipe is scarred, and it is generally easy to peel off without rooting.

cause:

1) Impurities in graphite lubricant.

2) The iron ears at the rear end of the waste pipe are pressed into the inner wall of the steel pipe, etc.

Inspection: The inner surface of the steel pipe is not allowed to exist, the pipe end should be ground and re-cut, the depth of the grinding should not exceed the negative deviation required by the standard, the actual wall thickness should not be less than the minimum value of the standard;

3.Lifting skin

Features: The inner surface of the steel tube presents a straight or intermittent nail-shaped lifting skin. Mostly appear in the head of the capillary and are easy to peel off.

cause:

1) Improper adjustment parameters of the punching machine.

2) Stick steel on top.

3) The accumulation of iron oxide scale in the waste pipe, etc.

Inspection: The inner surface of the steel pipe is allowed to have no root peeling easily (or can be burned off during heat treatment). The rooted skin should be sharpened or removed.

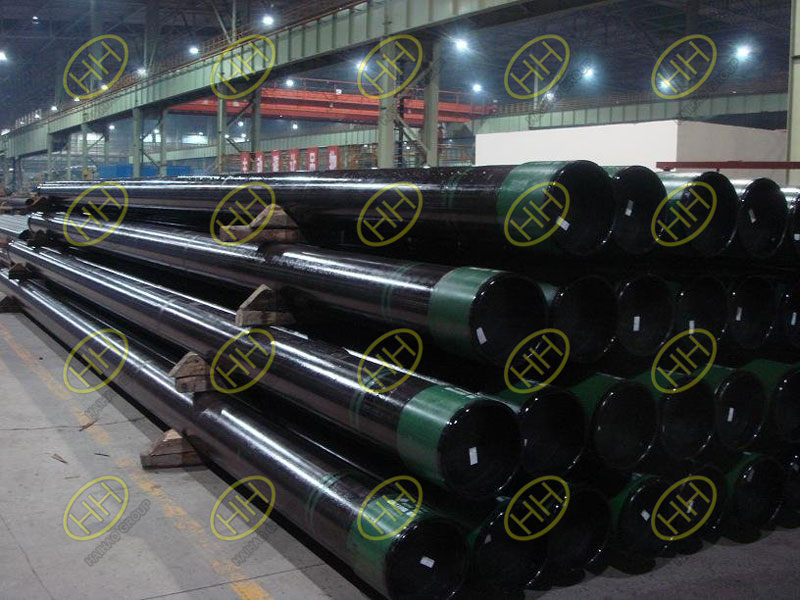

API 5CT PLS1 casing steel pipes

4.Inside straight

Features: There are linear scratches with a certain width and depth on the inner surface of the steel pipe.

cause:

1) The rolling temperature is low, and the mandrel sticks to a metal hard object.

2) Graphite contains impurities, etc.

Prosecution:

1) The inner straight of the casing and general pipe is allowed to have a depth not exceeding 5% (the maximum depth of pressure vessels is 0.4mm).

Shen Duchao Chad Straight should be sharpened and excised.

2) The inner straights with sharp edges should be smoothed.

5.Inner edge

Features: There are linear protrusions with a certain width and depth on the inner surface of the steel pipe.

Cause:

The mandrel is badly worn, and the grinding is not smooth or too deep.

Prosecution:

1) The height of the casing and line pipe shall not exceed 8% of the wall thickness, and the maximum height shall not exceed 0.8mm, which will not affect the inner edge of the diameter. Out of tolerance should be repaired and recut.

2) General pipes and line pipes are allowed to have inner edges with a height not exceeding 8% of the wall thickness (maximum height is 0.8mm). Out-of-tolerance should be sharpened and recut.

3) For L2 (ie N5) flaw detection requirements, the height of the inner edge must not exceed 5% (maximum height is 0.5mm). Out-of-tolerance should be sharpened and recut.

4) Sharp inner edges should be sharpened and smoothed.

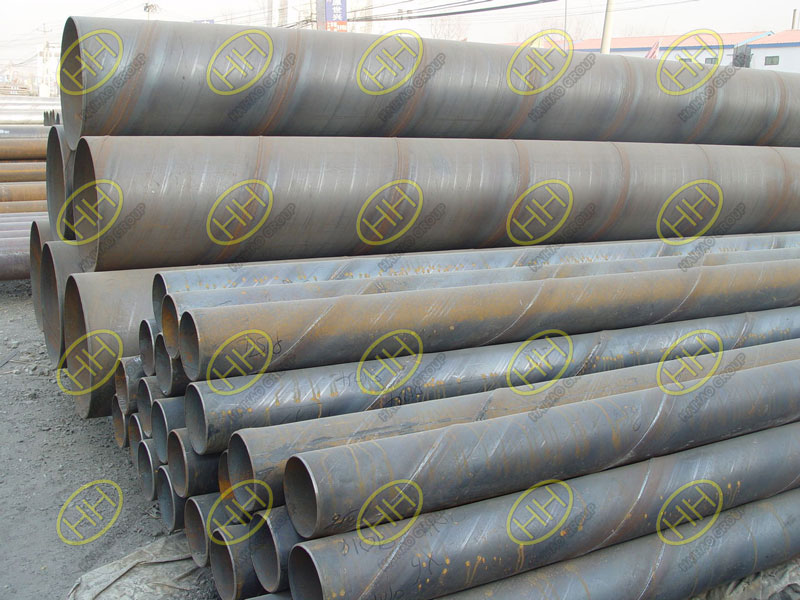

Spiral welded pipes in Haihao Group

6.Inner drum kit

Features: The inner surface of the steel pipe is regularly convex and the outer surface is not damaged.

Causes: The excessive grinding amount of the continuous rolls or meat loss.

Judgment: Judging according to the requirements of the inner edge.

7.Lag

Features: The inner surface of the steel pipe is regularly or irregularly pitted and the outer surface is not damaged.

Cause:

1) Improper adjustment of continuous rolling, the rolling speed of each stand does not match.

2) The tube blank is heated unevenly or the temperature is too low.

3) The rolling center line is deviated, the collision between the steel pipe and the roller table after continuous rolling, etc. (Note: This reason was proposed in 2003. The principle is still under discussion).

Judgment: The negative deviation of the wall thickness is not exceeded, and the actual wall thickness is greater than the minimum required wall thickness. Excessive pits should be removed. (Note: Serious development of lacing is crazing, and such injuries should be strictly inspected).

8.Internal thread (this defect only occurs in the Axel unit)

Features: There are spiral marks on the inner surface of the steel pipe, which mostly appear on the inner surface of the thin-walled pipe, with an obvious uneven feel. cause:

1) The inherent defects of the cross-rolling process. This defect is more prominent when the process parameters of the Axel tube rolling mill are not adjusted properly.

2) The distribution of deformation is unreasonable, and the reduction of Acer wall is too large.

3) Improper configuration of Axel rolls.

Inspection: The depth of the internal thread defect of the steel pipe is not more than 0.3mm, and is within a certain tolerance range.