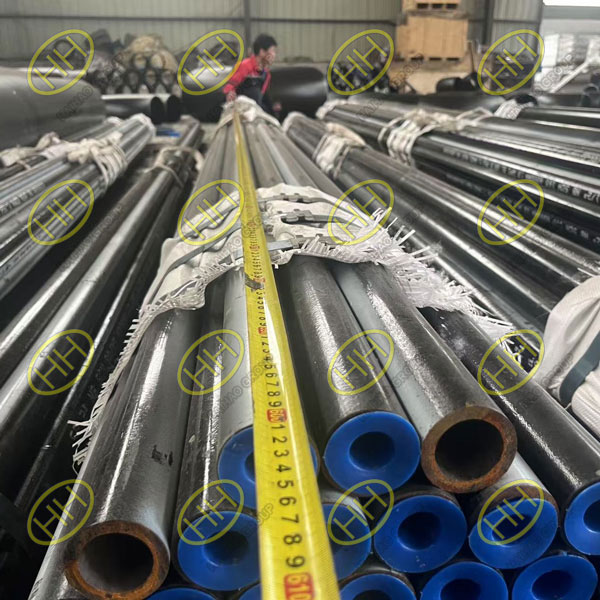

In critical oil and gas applications, selecting the right piping material is key to ensuring performance, safety, and long-term reliability. Recently, Haihao Group supplied a batch of API 5L GR. B seamless steel pipes to a major client in Singapore. These pipes were manufactured in compliance with ASME B36.10 dimensional standards and the NACE MR0175 material requirement for sour service.

But what makes API 5L GR. B seamless pipes a preferred choice for demanding pipeline systems? Let’s take a closer look.

API 5L GR. B Seamless Steel Pipes

What Is API 5L GR. B Seamless Steel Pipe?

API 5L GR. B is a specification under the American Petroleum Institute (API) standard for line pipes used in the transportation of oil, gas, and water. Grade B is one of the most widely used grades due to its good balance of strength, toughness, and weldability.

Seamless steel pipes, compared to welded alternatives, are manufactured without any weld seam. This gives them higher pressure tolerance and superior structural integrity, especially in high-stress environments.

Compliant with ASME B36.10 Dimensional Standard

The pipes Haihao Group supplied were produced following ASME B36.10, which governs the dimensions of seamless and welded carbon steel pipes. This ensures:

1.Consistent outer diameter and wall thickness

2.Dimensional compatibility with standard fittings and flanges

3.Standardized tolerances suitable for international projects

ASME B36.10 compliance guarantees easy integration into broader pipeline systems, especially for clients managing large-scale EPC projects.

Certified for Sour Service – NACE MR0175 Compliance

Corrosive environments, particularly those containing hydrogen sulfide (H₂S), require materials that can withstand sulfide stress cracking (SSC). That’s why Haihao Group’s seamless steel pipes for this project were also manufactured in accordance with NACE MR0175 / ISO 15156, making them suitable for sour gas service.

Benefits of NACE-compliant API 5L GR. B seamless pipes include:

1.Resistance to hydrogen-induced cracking (HIC)

2.Safe use in offshore oil and gas fields

3.Compatibility with aggressive chemical and gas media

Key Features of API 5L GR. B Seamless Pipe

| Property | Value |

| Material Standard | API 5L GR. B |

| Pipe Type | Seamless |

| Outer Diameter Range | 1/2″ – 24″ (depending on wall thickness) |

| Manufacturing Tolerance | As per ASME B36.10 |

| Pressure Rating | Suitable for medium to high-pressure lines |

| Surface Finish | Black-painted, bare, or coated |

| End Finish | Plain end, beveled, or threaded |

Common Applications

API 5L GR. B seamless steel pipes are widely used in:

- Onshore and offshore oil and gas pipelines

- Petrochemical transmission systems

- Water injection lines

- Power plant heat recovery systems

- Refinery piping projects

Their high tensile strength and structural resilience make them ideal for high-pressure and high-temperature services, especially when sour gases are involved.

Why Choose Haihao Group?

Haihao Group brings over 40 years of experience in manufacturing high-quality piping systems. For this Singapore project, all pipes were:

- 100% dimensionally inspected

- Subject to hydrostatic and non-destructive testing (NDT)

- Accompanied by complete EN 10204 3.1 material certificates

- Packaged for marine shipment with anti-corrosion protection

We work according to international specifications, with ISO, PED, and API certifications, ensuring reliability for your global projects.

Contact Us

Looking for reliable API 5L GR. B seamless steel pipes for your next pipeline or offshore project? Haihao Group is your one-stop supplier for line pipe, fittings, flanges, and pressure components. Email:sales@haihaogroup.com