Socket welding(SW) is the welding method of pipeline insertion,which forms a fillet welds.It is generally used for small-diameter welding,the commonly used specification is DN50 or less,of course,the size can be up to DN100 4″ in the standards.

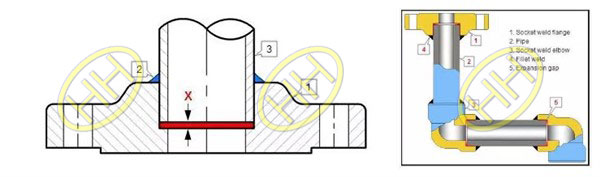

Socket weld drawing

1.welded flange 2.welded seam 3.pipe fittings

The production of socket welding generally include socket weld flanges,socket weld elbows,socket weld tees,socket weld coupling and so on.

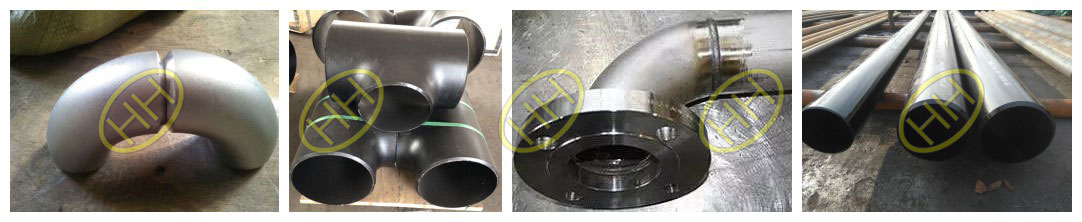

Socket weld flange tee elbow union

Butt welding(BW) is the welding of pipe fittings,pipe fittings,flanges or pipes.

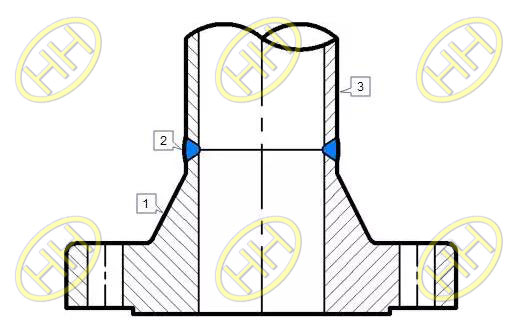

Butt weld draw

1.welded flange 2.welded seam 3.pipe fittings

This type of welding is the most common method of pipe connection.Generally this kind of production include steel pipes,weld neck flanges,butt weld elbows,butt weld tee and butt weld reducers…

Butt weld elbow tee flange steel pipe

The difference between socket welding and butt welding is as follows:

1.Diameter:

Socket welding is suitable for a small diameter,this kind of welding is generally suitable for the size below DN50.

Butt welding is suitable for a wide range of size.

2.End:

The normal butt welding end must be made to a bevel end of 30~40°,which is convenient for welding and filling of welding material. Of course, super wall thickness will make the compound bevel end.

Socket welding does not need to the process,suitable for direct welding.

3.Welded seam:

The socket welding seams are fillet welds.

The butt welding seams are butt welds,and there is a high requirement for welding, but also can bear very high pressure.

4.Non-destructive testing:

Nondestructive testing of socket welding is magnetic particle testing or penetration testing, stainless steel is penetration testing,and carbon steel is magnetic particle testing commonly.

Butt welding uses 100% RT inspection (commonly X-ray).