There are various pipe fittings manufacturing process that used to manufactured elbow, tee, reducers and other pipe fittings.

Fittings are manufactured from seamless pipe and from welded Pipe.Large diameter fittings are manufactured from Plate.

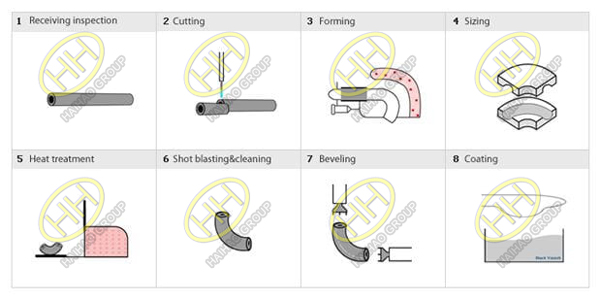

Elbows Manufacturing Process:

Hot Forming

- One of the most common Pipe Fittings Manufacturing Process for manufacturing Elbows from the pipe is mandrel method which is kind of hot forming methods.

- In this method, the pipe is cut in pieces and push with the help of hydraulic ram. Induction heating coil heats the pipe and, it is pushed over a die called “mandrel” which allows the pipe to expand and bend simultaneously.

- This method can be used to manufacture a wide range of the diameter of elbows

Hot forming process of elbow

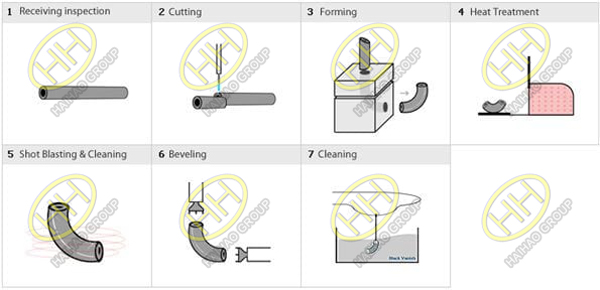

Extrusion Method

In cold Extrusion method, a pipe with the same diameter as finished product is pushed through a die and formed into its desired shape. Usually applied to stainless steel small to medium sizes elbows.

Extrusion method of elbow

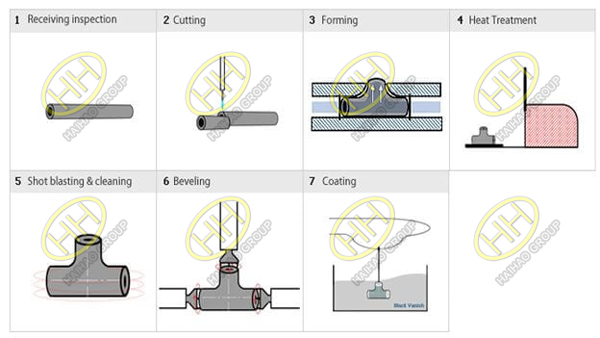

Tee Manufacturing Process:

Hydraulic Bulge Method

Hydraulic Bulge method is used to manufacture Tee. Cut piece of Pipe is placed in hydraulic die and liquid is fill inside the pipe, Hydraulic pressure pushes out the branch, in the fixed opening in the die. This method gives the good surface finish. However, higher thickness Tee cannot be manufactured by this method.

Hydraulic bulge method of tee

Hot Extrusion Method

Tee with large diameters, heavy wall thickness and /or special material with challenging workability that cannot be manufactured using the hydraulic bulge method are manufactured using hot Extrusion Method. In hot Extrusion Method, Normally Bigger diameter pipe is used than the finished product size, the branch outlet is extruded from the pipe with help of extrusion tool. Other dimensions of body and branch can also be adjusted by pressing the die if required.

Hot extrusion method of tee

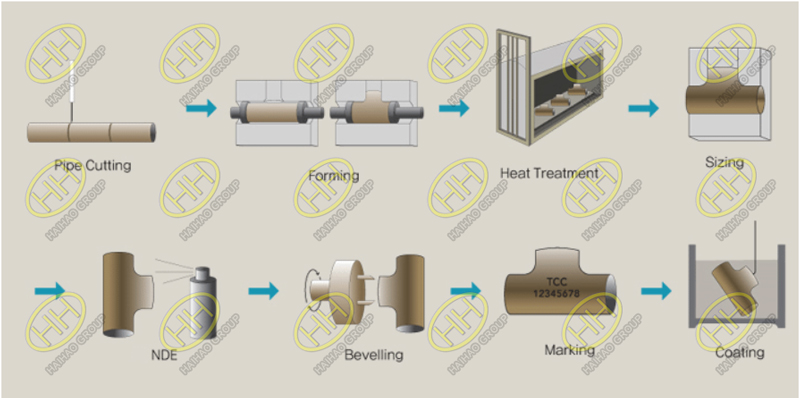

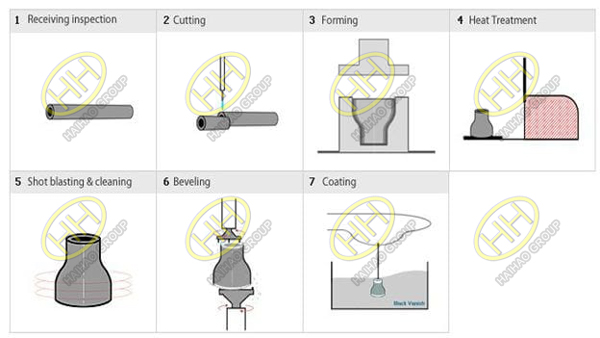

Reducer Manufacturing Process:

Outer Die Method

Most common method for manufacturing Reducers is Outer Die method. The pipe is cut and pressed in the outer die; compressing the one end of the pipe into a smaller size. This method is useful for manufacturing of small to medium size of reducers.

Outer die method of reducer

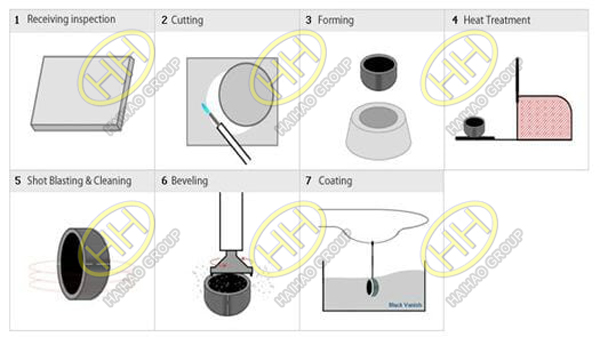

Cap Manufacturing Process:

Deep Drawing Method

CAPS are manufactured by Deep Drawing method. In this method, Plate is cut out in a circle and formed by deep drawing die.

Deep drawing method of cap

As a professional piping supplier,Haihao Group supply elbows,bends,tees,reducers,caps and other pipe fittings in different manufacturing process.If you want to know more about our products.Please feel free to contact us.Email:sales@haihaogroup.com